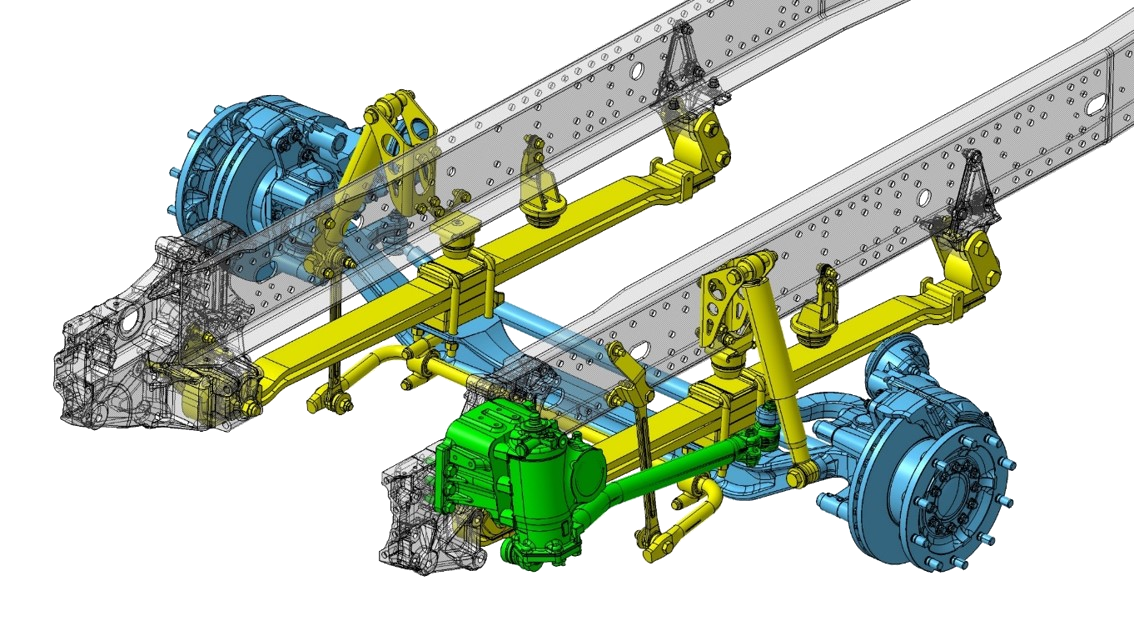

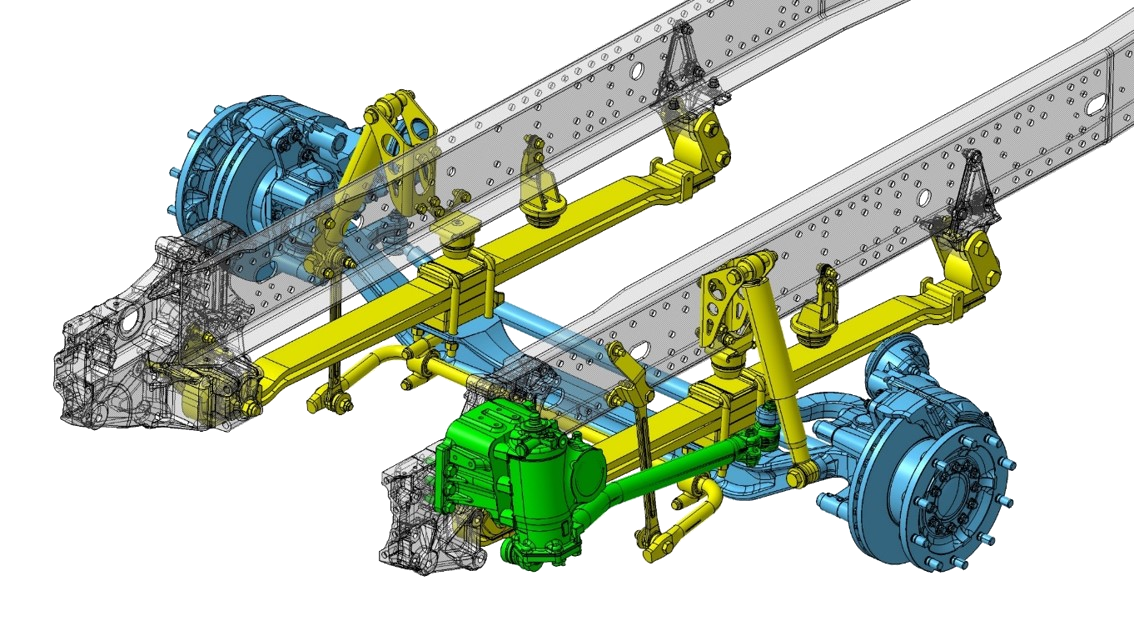

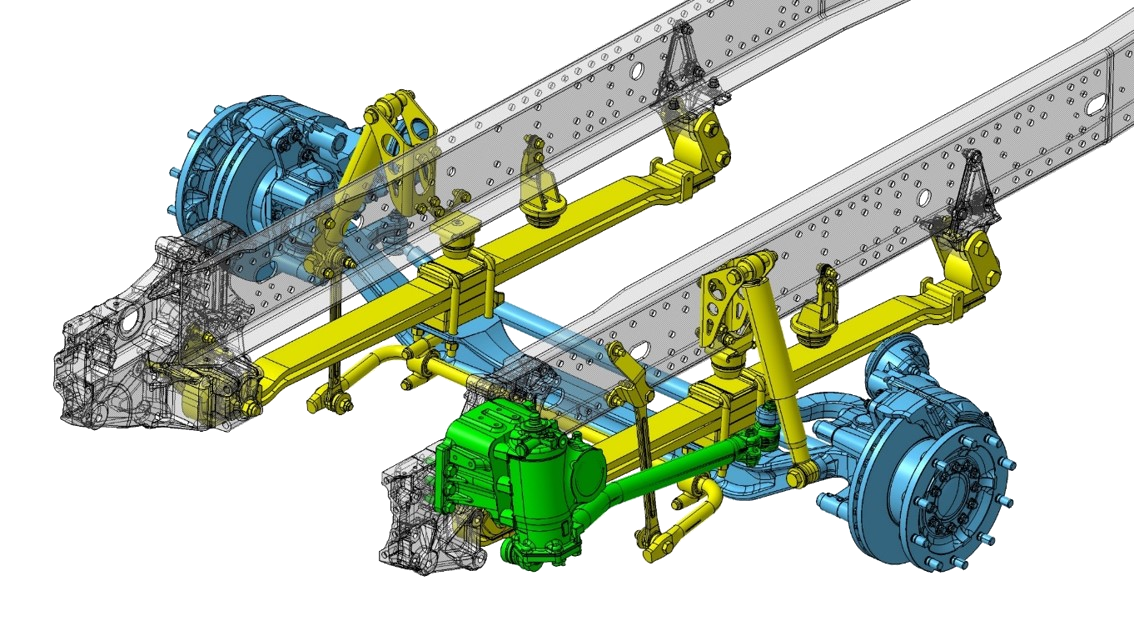

Axle

Leafspring

Leafspring

Vehicle Frame

Vehicle Frame

Steering gear

Shock Absorber

Shock Absorber

Stabilizer

The project aims at developing an enhanced R&D procedure for the systematic development of downweighted axle suspension components with high requirements on durability and safety.This enhanced R&D procedure will be fatigue orientated, leading to best exploitation of materials and processes in a systematic and physically reasonable way. It will affect all stages of development, from the earliest, conceptual stage until the final experimental durability approval. The individual project objectives described beneath set the fundamental steps within the new R&D procedure. In particular:

The project "SLIMSUSPENSION: Novel methods for design and develpment of lightweight, high-performance axle suspensions of road trasporttation vehicles and for durability testing on triaxial 6-channel testing rig" (Project No Τ7ΔΚΙ-00054 ) has been realized under the National Action “Bilateral and Multilateral R&T Cooperations, Bilateral and Multilateral R&T cooperration between Greece and China”, and co‐financed by the European Regional Development Fund of the European Union and Greek national funds through the Operational Program Competitiveness, Entrepreneurship and Innovation.

Το έργο SLIMSUSPENSION υλοποιήθηκε στο πλαίσιο της Δράσης “ΔΡΑΣΗ ΕΘΝΙΚΗΣ ΕΜΒΕΛΕΙΑΣ: ΔΙΜΕΡΕΙΣ ΚΑΙ ΠΟΛΥΜΕΡΕΙΣ Ε&Τ ΣΥΝΕΡΓΑΣΙΕΣ, Διμερής και Πολυμερής Ε&Τ Συνεργασία Ελλάδας-Κίνας” και συγχρηματοδοτήθηκε από το Ευρωπαϊκό Ταμείο Περιφερειακής Ανάπτυξης (ΕΤΠΑ) της Ευρωπαϊκής Ένωσης και από εθνικούς πόρους μέσω του Ε.Π. Ανταγωνιστικότητα, Επιχειρηματικότητα & Καινοτομία (ΕΠΑνΕΚ) (κωδικός έργου: Τ7ΔΚΙ-00054).

The determination of the mechanical (static, fatigue) properties of the materials used for the main suspension components (springs, stabilizer bars), as well as the contribution of specific treatments (heat-treatment, shot-peening, stress-peening, etc.) to the resulting fatigue life

The development and the experimental validation of a novel, material mechanics based fatigue design model, applicable already in the earliest, conceptual design phase of axle suspension components. This model will be implemented in the R&D departments of both industrial project partners in order to be immediately exploited for any future product development. For this, it will be linked to geometrically non-linear FE-based models used nowadays for the theoretical simulation and determination of the suspension kinematics and stress behavior in the vehicle assembly configuration under monotonic loads.

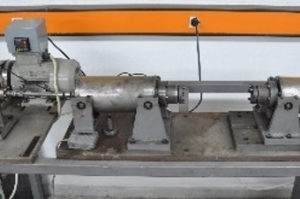

The design and construction of a worldwide unique triaxial 6-channel testing platform capable to apply all fatigue life affecting driving maneuvers on complete suspensions. Within the project’s framework it will be used for the experimental durability approval of the lightweight suspension components and the complete suspension system. Beyond the present project, the test rig will be immediately exploited for advanced testing of all future suspension components. AUTH, as the designer and IPR holder of the test rig design, will also exploit this project outcome. AUTH intends to construct a similar test rig to provide advanced testing services to European OEMs and suspension product suppliers.

The elaboration of R&D guidelines describing precisely the procedures to be followed for designing and testing of lightweight suspension components and systems, exploiting therewith all project outcomes immediately on industrial scale.

Axle

Leafspring

Leafspring

Vehicle Frame

Vehicle Frame

Steering gear

Shock Absorber

Shock Absorber

Stabilizer

Slim Suspension | Laboratory of Machine Elements and Machine Design | Aristotle University of Thessaloniki, Copyright © 2021 All Rights Reserved